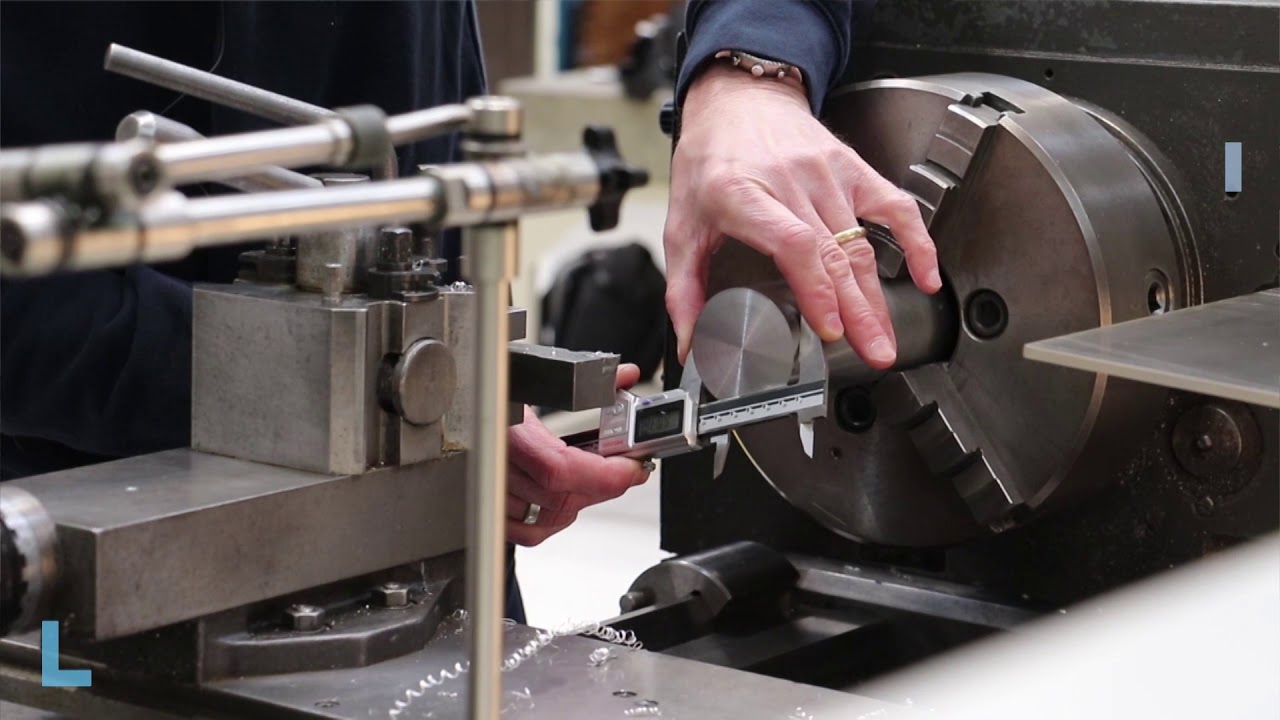

Mechanical processing

In 2017, Flexon-All SRL implemented the project “Increasing the competitiveness of Flexon-All by diversifying the activity”, SMIS code 115167 within the Regional Operational Program 2014 – 2020, Priority Axis 2 – Improving the competitiveness of small and medium enterprises, Priority Investment 2.2 – Supporting the creation and expansion of advanced production capacities and the development of services.

As a result of this project, we have significantly enhanced our production capabilities. We now operate with an expanded range of CNC turning and milling machines, including advanced 2-axis and 4-axis models. Our production is carried out by a team of skilled personnel trained in various mechanical processing operations, including turning, milling, grinding, and more. Also, our production equipment includes turning machines (diameter up to Ø980mm and length up to 6000 mm), milling machines (diameter up to Ø400 and length up to 2000 mm), round grinding machines (diameter up to Ø350 mm and length up to 1000 mm), flat grinding machines (height up to 250 mm, length up to 1500 mm and width up to 300mm).

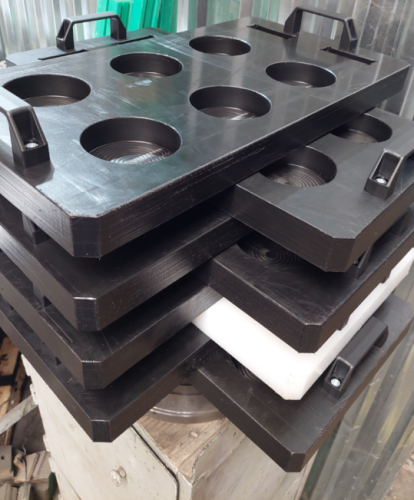

With these technologies and expertise, we are capable of designing and manufacturing a wide variety of products. Our offerings include spare parts, copper couplings, tightening couplings, shock absorbers, bottle molds, polyamide star wheels, polyacetal toothed sectors, molds for thread protections, HD1000 sleeves, and dural support switches. We are dedicated to delivering high-quality products tailored to meet our clients’ specific needs.

Enquire with us to see how we can assist with your manufacturing requirements and provide innovative solutions for your projects.

We are always ready to help you and answer your questions